How Aluminized Steel is Made

Block Steel has been a reliable source for quality steel products for more than 70 years. Specializing in aluminized steel for clients in different industries throughout the country, we can provide you with quality aluminized and stainless steel products, cut to your specifications, so it’s ready to go into production when it arrives at your facility.

The Aluminized Steel Process

- Base Steel Selection

The process starts with a sheet of cold-rolled carbon steel, which has a unique combination of strength and formability.

- Cleaning

The steel is then cleaned thoroughly to remove dirt, oil, or any other contaminants to ensure that the aluminum coating adheres to the steel properly.

- Hot-Dip Coating

Now that the steel has been properly cleaned, it is passed through a bath of molten aluminum at temperatures around 1220 degrees Fahrenheit. This is similar to the process of making galvanized steel, but with the use of an aluminum or aluminum-silicon alloy instead of zinc.

- The most common type of aluminized steel is coated with an aluminum-silicon alloy (usually 90% aluminum and 10% silicon).

- The silicon helps improve adherence and prevents the formation of brittle layers.

- Cooling and Solidification

The coated steel is then cooled rapidly using water or air jets after the aluminum bath to solidify the aluminum-silicon layer.

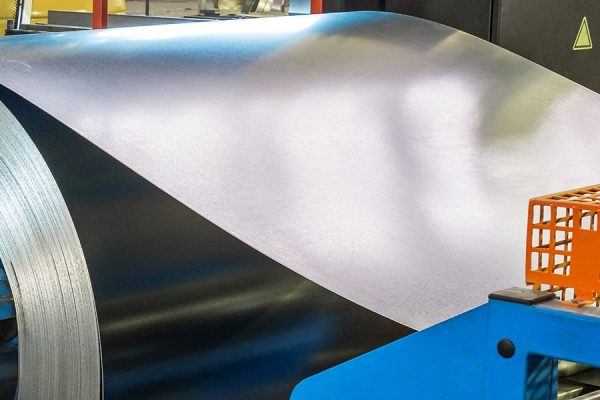

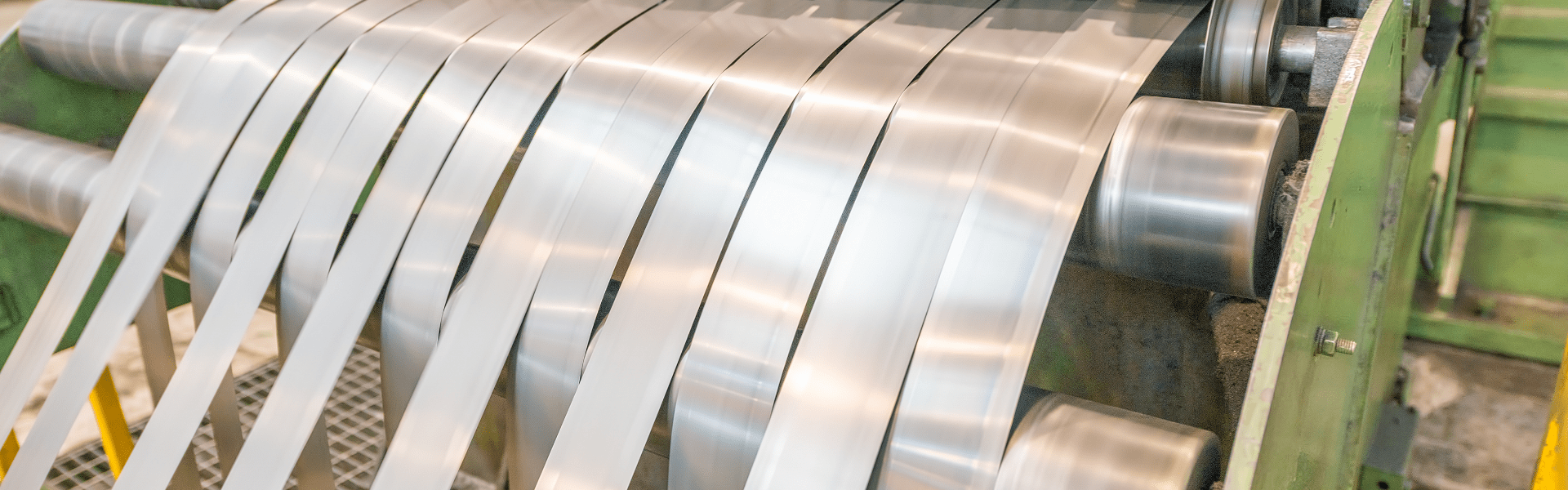

- Finishing

Once completely cooled, the aluminized steel is leveled, coiled, or cut into the desired shapes or sheets. The steel may also go through additional treatments like passivation to help enhance resistance to corrosion.

Key Characteristics

- Corrosion Resistance (Especially Heat-Related)

- Reflectivity (Due to Aluminum Coating)

- Heat Resistance (up to 900°F or more)

These characteristics make aluminized steel a popular choice in the production of automotive parts, ovens, furnaces, exhaust systems, and other applications where extreme heat is present. For more information about how Block Steel can provide you with the aluminized steel you need for your business, please contact us today!